Camera Bellows

During the development of the Camera Module v2, a practical and low-cost solution was found for constructing light-tight camera bellows using thick acoustic molton. The material used is 500g/m² stage-grade molton, which offers both the necessary opacity and pliability. The bellows were made by sewing together two equally 320 mm squares of the fabric, each with a centered cutout to accommodate optical passage. Once sewn, the assembly was turned inside out to conceal the seams and provide a clean outer appearance.

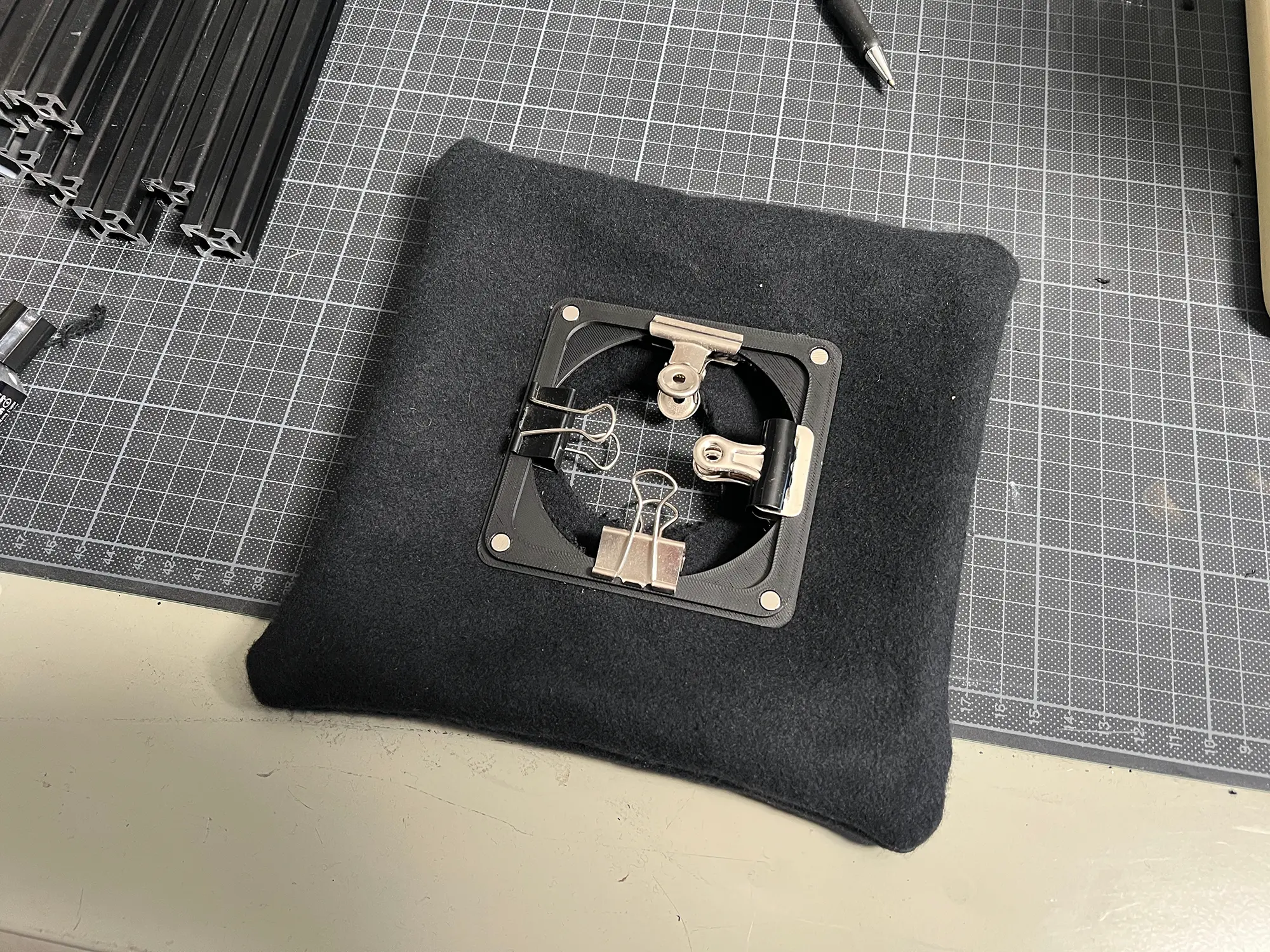

To complete the structure, the bellows were glued to their rigid front and rear bellow boards using contact adhesive. These 3D-printed parts specifically designed for the Splicer are available in the GitHub repository, see links below. Small neodymium magnets (3×6 mm) were glued into dedicated recesses in the bellow boards using thick cyanoacrylate adhesive. These allow the bellows to snap securely into place, attaching magnetically both to the lensboard / RGB Filter Changer and the toolhead, ensuring light-tightness and modular handling. The resulting bellows are lightweight, fully opaque, and robust enough for repeated mounting and dismounting.